Welding Machines

Leister develops and manufactures automatic welders and welding machines that are used to weld thermoplastic membranes on roofs, landfills, tunnels, truck tarpaulins and shading systems.

Leister develops and manufactures automatic welders and welding machines that are used to weld thermoplastic membranes on roofs, landfills, tunnels, truck tarpaulins and shading systems.

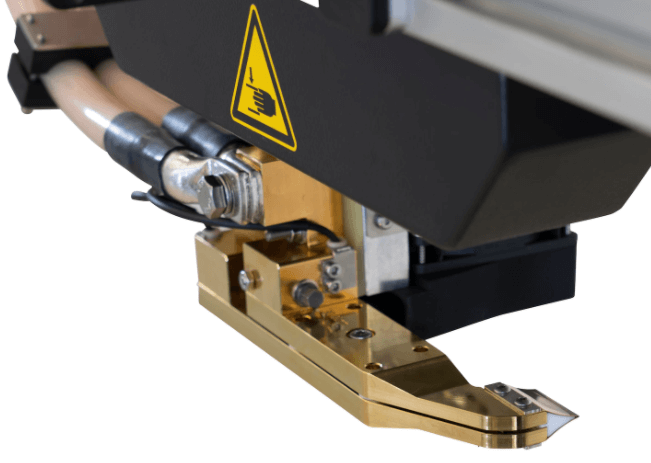

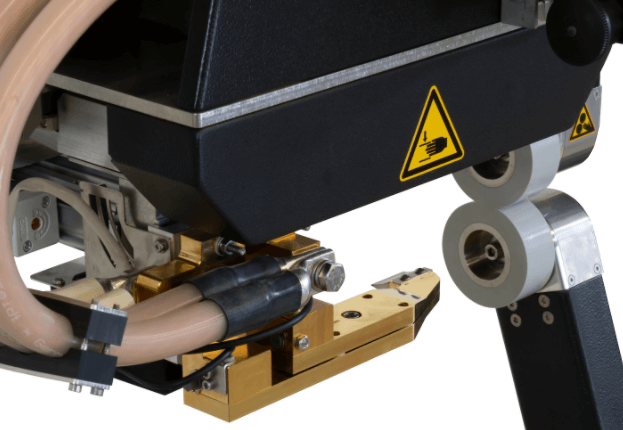

The SEAMTEK W-900 AT is the first welding machine to feature the innovative low voltage hot-wedge technology from Leister. This new welding machine is based on the proven SEAMTEK 900 AT. During critical points, the speed can be reduced, similar to a sewing machine, simply and without interruption of the welding process. This innovative plastic welding technology guarantees high-quality welding seams. This is also true for delicate materials.

| NAME | METRIC | IMPERIAL |

|---|---|---|

| VOLTAGE | 230 - 240 V | 230 - 240 V |

| FREQUENCY | 50/60 Hz | 50/60 Hz |

| POWER | 3900 W | 3900 W |

| TEMPERATURE | 0 - 680 °C | 32.0 - 1256.0 °F |

| SPEED | 0.5 - 30.0 m/min | 1.64 - 98.43 ft/min |

| LENGTH | 1500.0 mm | 59.05 in |

| WIDTH | 702.0 mm | 27.63 in |

| HEIGHT | 1500.0 mm | 59.05 in |

| WEIGHT | 238.0 kg | 524.7 lb |

| PLUG | without plug | without plug |

| POWER CABLE LENGTH | 2.0 m | 6.56 ft |

| CONFORMITY MARK | CE | CE |

| PROTECTION CLASS | I | I |

The hot wedge heats up immediately at the start of the welding process.

Operating Instructions

SEAMTEK W-900 AT/W-2000 AT

SEAMTEK-W-900-AT_W-2000-AT.pdf (130 downloads)

General Catalogue

Plastic Welding

Plastic-Welding-1.pdf (1822 downloads)