Welding Machines

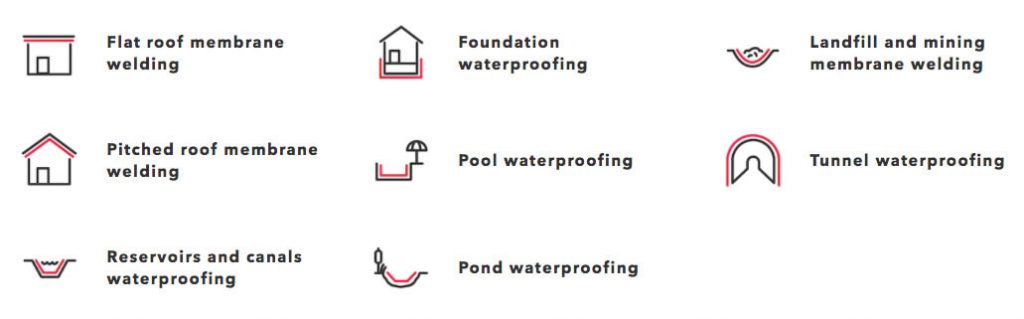

Leister develops and manufactures automatic welders and welding machines that are used to weld thermoplastic membranes on roofs, landfills, tunnels, truck tarpaulins and shading systems.

Leister develops and manufactures automatic welders and welding machines that are used to weld thermoplastic membranes on roofs, landfills, tunnels, truck tarpaulins and shading systems.

The UNIDRIVE 500 semi-automatic welding machine combines manual and automatic welding in a 9.9 lb (4.5 kg) handy plastic welding device with a service-friendly brushless motor. Thanks to its overlap technology, it’s ideal for welding various thermoplastic membranes such as PVC and TPO.

| Voltage | Roll Material | Welding Nozzle / Seam Width | Plug |

|---|---|---|---|

| 100 V | Silicone roller 50 shore A | 40 mm | JP, 3 poles, 20A ⓘ |

| 230 V | Silicone roller 50 shore A Steel roller blunt diagonal |

15 mm / 30 mm / 40 mm | CEE blue, 3 poles, 16A ⓘ CH T12, 3 poles, 10A ⓘ EU, 3 poles, 16A ⓘ UK, 3 poles, 13A ⓘ US, 2 poles, 15A, polarized ⓘ |

| NAME | METRIC | IMPERIAL |

|---|---|---|

| VOLTAGE | 100 - 230 V | 100 - 230 V |

| POWER | 1500 - 2200 W | 1500 - 2200 W |

| TEMPERATURE | 100 - 560 °C | 212.0 - 1040.0 °F |

| SPEED | 0.7 - 4.5 m/min | 2.29 - 14.76 ft/min |

| ROLL MATERIAL | Steel roller blunt diagonal; Silicone roller 50 shore A | Steel roller blunt diagonal; Silicone roller 50 shore A |

| WELDING NOZZLE / SEAM WIDTH | 15 - 40 mm | 0.59 - 1.57 in |

| BRUSHLESS BLOWER MOTOR | Yes | Yes |

| BRUSHLESS DRIVE MOTOR | Yes | Yes |

| NOISE EMISSION LEVEL | 70 dB (A) | 70 dB (A) |

| DISPLAY | Yes | Yes |

| LENGTH | 275.0 mm | 10.82 in |

| WIDTH | 173.0 mm | 6.81 in |

| HEIGHT | 297.0 mm | 11.69 in |

| WEIGHT | 4.5 kg | 9.92 lb |

| PLUG | CEE blue, 3 poles, 16A; JP, 3 poles, 20A; EU, 3 poles, 16A; US, 2 poles, 15A, polarized; UK, 3 poles, 13A; CH T12, 3 poles, 10A | CEE blue, 3 poles, 16A; JP, 3 poles, 20A; EU, 3 poles, 16A; US, 2 poles, 15A, polarized; UK, 3 poles, 13A; CH T12, 3 poles, 10A |

| POWER CABLE LENGTH | 3.0 m | 9.84 ft |

| CONFORMITY MARK | CE | CE |

| PROTECTION CLASS | I | I |

Changing the drive from left to right or vice versa is a breeze

UNIDRIVE 500 Operating Instructions

UNIDRIVE-500_Catalogue.pdf (382 downloads )

Plastic Welding – General Catalogue

Plastic-Welding-1.pdf (4174 downloads )