UNIROOF 300

-

- Reliable roof welding machine with a digital display

- Excellent price-performance-ratio

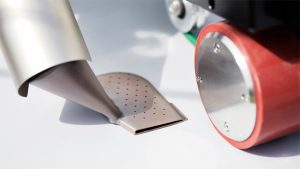

- Homogeneous weld seam thanks to the standard nozzle

- Low-maintenance drive motor

- Compact and light at only 17 kg (37.5 lbs)

Categories: LEISTER, ➤ Welding Auto Machine