Welding Machines

Leister develops and manufactures automatic welders and welding machines that are used to weld thermoplastic membranes on roofs, landfills, tunnels, truck tarpaulins and shading systems.

Leister develops and manufactures automatic welders and welding machines that are used to weld thermoplastic membranes on roofs, landfills, tunnels, truck tarpaulins and shading systems.

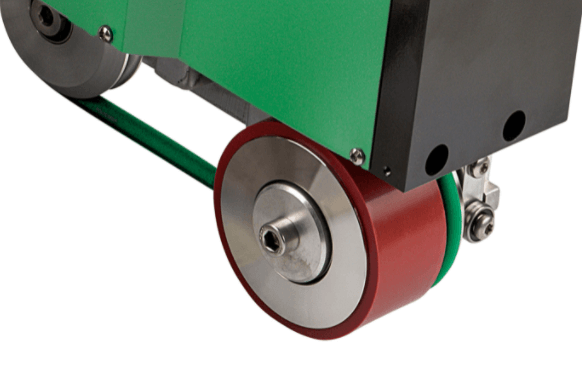

The VARIMAT S welding machine is a cost-effective, entry-level device for those who want to weld PVC membranes with proven Leister product quality. This automatic welder equips users with the same features as the BITUMAT and VARIMAT, ensuring perfectly welded PVC membranes. Thanks to its proven electronics with a manageable control circuit, i.e. the open-loop technology, VARIMAT S is a reliable partner on the job site.

| Voltage | Power | Welding Nozzle / Seam Width | Plug |

|---|---|---|---|

| 230 V | 4600 W | 40 mm | EU, 3 poles, 16A ⓘ |

| 400 V | 5700 W | 40 mm | CEE red, 5 poles, 16A ⓘ |

| NAME | METRIC | IMPERIAL |

|---|---|---|

| VOLTAGE | 230 - 400 V | 230 - 400 V |

| FREQUENCY | 50/60 Hz | 50/60 Hz |

| POWER | 4600 - 5700 W | 4600 - 5700 W |

| TEMPERATURE | 20 - 650 °C | 68.0 - 1202.0 °F |

| SPEED | 0.7 - 12.0 m/min | 2.29 - 39.37 ft/min |

| AIR VOLUME ADJUSTABLE ⓘ | Yes | Yes |

| WELDING NOZZLE / SEAM WIDTH | 40 mm | 1.57 in |

| BRUSHLESS BLOWER MOTOR | No | No |

| LQS ⓘ | No | No |

| LENGTH | 560.0 mm | 22.04 in |

| WIDTH | 430.0 mm | 16.92 in |

| HEIGHT | 330.0 mm | 12.99 in |

| WEIGHT | 28.0 kg | 61.72 lb |

| WELDING MATERIALS | PVC; TPE; EPDM | PVC; TPE; EPDM |

| PLUG | EU, 3 poles, 16A; CEE red, 5 poles, 16A | EU, 3 poles, 16A; CEE red, 5 poles, 16A |

| POWER CABLE LENGTH | 1.2 m | 3.93 ft |

| CONFORMITY MARK | CE | CE |

| PROTECTION CLASS | I | I |

Operating the VARIMAT S welding machine is easy with intuitive, conventional rotary buttons.

Thanks to the adjustable guide bar, the VARIMAT S can be easily transported.

VARIMAT S Operating Instructions

VARIMAT-S-Catalogue.pdf (172 downloads )

Plastic Welding – General Catalogue

Plastic-Welding-1.pdf (3616 downloads )