Industrial Hot Air Devices

Leister hot air tools are used in countless industrial production processes. In fact, there are very few industries that do not benefit from our versatile offerings, regardless if the process only operates with hot air or if it becomes more efficient with hot air. Leister has the right blower for every production line.

Details

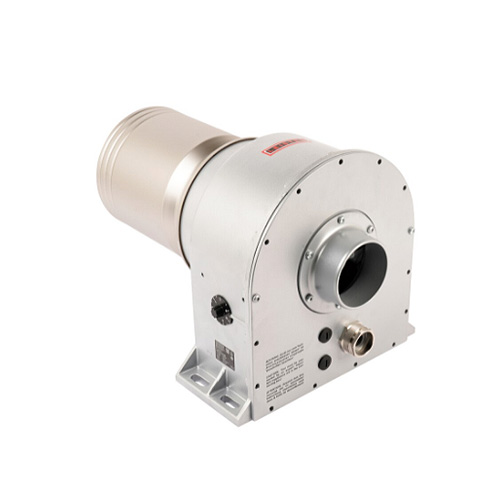

High-Performance Air Heater

With up to 40 kW, the LHS 91 SYSTEM is a high-performance air heater from Leister and a true hot air power package. It is used where large air volumes and high temperatures are required in continuous operation. With this output, the LHS 91 SYSTEM is able to replace gas heaters, thus increasing work safety and environmental friendliness. In addition, the LHS 91 SYSTEM can be individually adjusted to the respective requirements in industrial hot air systems, such as overlap nozzles, tubes and round nozzles, flange connections and extension tubes.

The LHS 91 SYSTEM is thus suitable for demanding industrial processes in drying and heating processes, welding and molding plastics. Additionally, it is used for separating and merging synthetic materials of all kinds, as well as sterilizing, mixing and dissolving foams. In order to prevent premature wear and to ensure the durability of the device, the air flow and ambient temperature should not exceed 60 °C / 140 °F. With the patented heating element and device overheating protection integrated, the air heater will report problems in a timely manner and prevent costly downtime. The LHS 91 SYSTEM version is also controllable like all LHS SYSTEM products via an integrated potentiometer or via interface with external CSS or PLC systems. With the LHS 91 SYSTEM, production methods are more efficient and more economical.

Highlights

For Demanding Industrial Processes

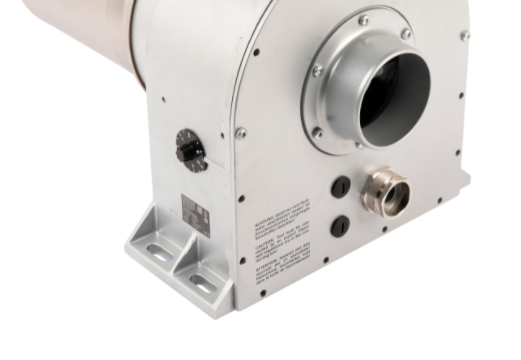

ROBUST

Durable Heating Element And Exterior

Immense stress, high temperatures or demanding materials do not matter to the LHS 91 SYSTEM.

It works reliably, thanks to innovative electronics as well as a dirt and stress-resistant housing made of cast aluminum.

STRONG

Heating Power Source With Peak Performance

With up to 40kW performance, the LHS 91 SYSTEM is unbeatable in the processing of plastic,

synthetic tissues, thin sheets, adhesives and other industrial methods in which process heat is required.

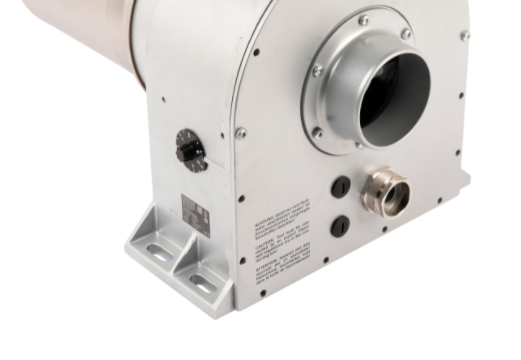

USER-FRIENDLY

Easy to operate, thanks to the potentiometer and interface

With the LHS 91 in the SYSTEM version, the heating output adjustment can be continuously variable via

the potentiometer and a control connection with the interface.

Downloads

Operating Instructions

LHS 91 Basic, LHS 91 System

LHS-91-Basic-LHS-91-System.pdf (178 downloads)

General Catalogue

Process Heat – US

Process-Heat-US.pdf (1449 downloads)